There are many avenues and ways to explore what goes into making a great cup of Dark Matter Coffee. With this post, we will help to explain all of those important parts by first starting with sourcing the coffee from the farm and how processing affects how coffee tastes.

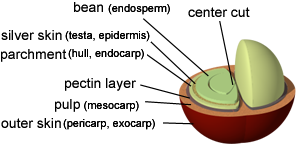

To begin, we will look at the anatomy of a coffee cherry, then move to explain different ways coffee is processed.

The Guts of a Coffee Cherry

Structure of coffee berry and beans: 1: outer skin/pulp 2:Mucilage/pectin layer 3: parchment 4: silver skin/chaff 5: bean/center cut

- Outer Skin / Pulp: The outer skin/pulp are covered by a skin, very similar to that of a cherry. This skin is usually removed from the fruit after the fruit is harvested. The exception is Natural Processed coffees, which leave the outer skin on during fermentation. The flesh, called cascara, is often recycled into compost at farms but has recently been used in making a drink that resembles a tea.

- Mucilage: After the skin comes the mucilage. This layer surrounds the coffee seeds with a sticky, sugary substance and gives the Honey process its name.

- Parchment: This is a cellulose layer that protects the coffee bean and resembles parchment paper when dried.

- Silver skin / Chaff: The final layer covering the seed is called silver skin due to it's silver-like sheen. During the roasting process this skin drys and falls off becoming chaff. Chaff is normally discarded waste but can be used in gardening and sometimes can be found in bags of coffee if it doesn't separate from the bean during the roasting process.

- Center Cut / Coffee Bean: The bean, THE GOOD STUFF, is what we are all searching for. Two seeds are found inside each coffee cherry, (Peaberries being an anomaly, with only one seed/bean inside. We will discuss this in a later post.) This is what we roast to DMC standards for the perfect coffee experience!

Main Processing Methods Used In Coffee

There are three main processing categories used in processing coffee. The difference between the three methods can be defined by the amount of layers of the layers listed above before being dried.

-

Natural or Dried in the Fruit Process – All the layers remain intact. This is the oldest and most direct way to process coffee. Careful attention must be paid to how the coffee is being dried to prevent any moldy or weird flavors don't get into the beans during the process. Coffees that use this method generally have a brighter, more fruit forward flavor profile.

-

Honey Process – The skin and pulp layers are removed while keeping a portion of the mucilage layer. Remember, this sugary layer is what defines the Honey process. These coffees have significantly less acidity than Washed or Natural coffees due to the short amount of time it takes for the mucilage to dry, resulting in less fermentation. The length of drying time and exposure to the sunlight will determine what type of Honey process it is called. Yellow, Red, or Black are descriptions used to help describe the length of time and amount of light exposure that each coffee receives during the drying process.

-

Yellow Honey Also known as semi-washed, this coffee is rinsed with minimal water to wash off excess mucilage. Later, it is exposed to direct sunlight to dry quickly and control fermentation, this style of processing is the least fermented of the "honey" processes and is effective for boosting body and sweetness in a cup.

(This is a machine washer for coffee turned up to its most powerful setting. It is used for the "yellow honey" or semi-washed process. Though Federico Pacas says, this style would be more like "white honey" when used to this extreme. The cherries are moved up while the mucilage is dripping down to leave just a touch of that magical Miel on, before the dry fermentation and then off the drying beds)

(This is a machine washer for coffee turned up to its most powerful setting. It is used for the "yellow honey" or semi-washed process. Though Federico Pacas says, this style would be more like "white honey" when used to this extreme. The cherries are moved up while the mucilage is dripping down to leave just a touch of that magical Miel on, before the dry fermentation and then off the drying beds)

-

Red Honey This process does not necessitate water and instead is dry-pulped and exposed to direct sunlight up to a period of two to three weeks. Slightly more acidity is present in the cup but also maintains a great deal of sweetness.

-

Black Honey The most labor-intensive of the honey processed coffees due to the longest drying times and intentionally sheltered from the light to allow yeast and bacteria to thrive and produce higher amounts of acidity. Some of its characteristics in the cup can be similiar to that of a natural due to the extended fermentation process.

(Aaron Campos, Dir of Coffee for DMC, and Federico Pacas look over black honey processed bourbon cultivars from Finca San Jose in El Salvador!)

-

Washed Process –This process is also called wet processed because the skin, pulp and mucilage are all removed using water and fermentation. In this method, a machine called a depulper removes the skin of the coffee cherry. Fermentation tanks are the next destination, with the coffee remaining in the water until the mucilage is broken down and the beans are no longer sticky. If the green coffee is left in the water too long, over-fermentation can happen, with the results being a sour tasting coffee. The washing process is a neutral expression of fermentation as it only yields characteristics natural to the cultivar - bacteria and yeast do not produce esters or acids to alter flavors in the cup.

(This is a machine washer for coffee turned up to its most powerful setting. It is used for the "yellow honey" or semi-washed process. Though Federico Pacas says, this style would be more like "white honey" when used to this extreme. The cherries are moved up while the mucilage is dripping down to leave just a touch of that magical Miel on, before the dry fermentation and then off the drying beds)

(This is a machine washer for coffee turned up to its most powerful setting. It is used for the "yellow honey" or semi-washed process. Though Federico Pacas says, this style would be more like "white honey" when used to this extreme. The cherries are moved up while the mucilage is dripping down to leave just a touch of that magical Miel on, before the dry fermentation and then off the drying beds)

Comments

At last ,a good point to start processing my own coffee at home

Great info. Planning to have a complete processing plant from crude coffee input to end product(packaging) the best quality coffee.

Good literature. Would like to have an assembly of a coffee wet processing structure with measurements. Quantification of materials for the structures necessary. In Kenya.